JN-Engineering Wind Tunnel Project

Authors: Jacob Poore (Jacob-Poore) & Noah Lim (Lim-Noah)

Repository: github.com/JN-Engineering/wind-tunnel

Last Updated: October 4, 2025

1. PROJECT OVERVIEW

1.1 Purpose

This document compares two build configurations for our closed-circuit wind tunnel project:

- Config A (Budget Build): Educational/demo facility with manual instrumentation

- Config B (Research Build): Automated data acquisition with improved material quality and enhanced structure

We are weighing whether to build a low-cost version—making the educational investment more easily replicable for future students, or to invest upfront in higher-quality instrumentation. This analysis compares actual component costs and capabilities to guide our decision.

2. CONFIGURATION A: BUDGET BUILD

2.1 Complete Bill of Materials

| Line | Source | Description | Notes | Qty | Unit Cost ($) | Total Cost ($) | Category |

|---|---|---|---|---|---|---|---|

| 1 | Amazon | PLA Filament, 1.75 mm | 1 kg spool | 5 | 28.00 | 140.00 | Materials & Structure |

| 2 | Home Depot | Acrylic Sheets | 24″ × 36″ | 3 | 32.09 | 96.27 | Materials & Structure |

| 3 | Home Depot | MDF Board | 16″ × 20″ | 10 | 9.00 | 90.00 | Materials & Structure |

| 4 | Home Depot | Plywood | 4′ × 4′ | 4 | 22.00 | 88.00 | Materials & Structure |

| 5 | Fabricated | Modular Wall Panels | cut from wood/acrylic | 36 | 0.00 | 0.00 | Materials & Structure |

| 6 | Fabricated | Contraction Nozzle | MDF/3D printed | 1 | 0.00 | 0.00 | Materials & Structure |

| 7 | Fabricated | Observation Panels | Acrylic windows | 3 | 0.00 | 0.00 | Materials & Structure |

| 8 | Unknown | Silicone Rubber Sheet | High-temp gasket | 1 | 10.00 | 10.00 | Materials & Structure |

| 9 | Unknown | Fasteners M3–M8 | Assorted | 1 | 10.00 | 10.00 | Materials & Structure |

| 10 | Unknown | Load Cell 0–5 kg | Analog output | 3 | 15.00 | 45.00 | Instrument & Data |

| 11 | Fabricated | Model Hardware Mount | 1 | 0.00 | 0.00 | Instrument & Data | |

| 12 | Unknown | ADC Module | e.g., HX711 | 1 | 4.00 | 4.00 | Instrument & Data |

| 13 | Unknown | Pitot Tube | Velocity measurement | 1 | 5.00 | 5.00 | Instrument & Data |

| 14 | Unknown | Differential Pressure Sensor | Analog | 1 | 15.00 | 15.00 | Instrument & Data |

| 15 | Fabricated | Flow Straightener | Honeycomb/fabricated | 1 | 0.00 | 0.00 | Air Flow |

| 16 | Fabricated | Turbulence Screens | Fine mesh | 2 | 0.00 | 0.00 | Air Flow |

| 17 | Salvaged | Axial Fan | 1 | 0.00 | 0.00 | Air Flow | |

| 18 | Unknown | Micro Servo | Generic RC servo | 1 | 15.00 | 15.00 | Control & Electrical |

| 19 | Unknown | Arduino Uno R3 | Controller | 1 | 25.00 | 25.00 | Control & Electrical |

| 20 | Unknown | 12 V Power Supply | Wall adapter | 1 | 10.00 | 10.00 | Control & Electrical |

| 21 | Unknown | Adhesives & Consumables | Epoxy, drill bits | 1 | 6.00 | 6.00 | Contingency & Misc |

| 22 | N/A | Project Contingency Reserve | Shipping/misc | 1 | 20.00 | 20.00 | Contingency & Misc |

Configuration A Total: $579.27

2.2 Equipment List

| Equipment | Description | Notes | Unit Cost ($) | Total Cost ($) |

|---|---|---|---|---|

| Bamboo H2D | 3D Printer | Used for fabricating PLA structural parts and small fixtures | 0 | 0 |

| EPILOG HELIX | Laser Cutter | Used for cutting acrylic panels and MDF sheets | 0 | 0 |

| Fog Machine | Airflow Visualization Device | Using propylene glycol fluid; Alternatively scavenged heating elements | 40 | 40 |

| Safety | Eye Protection, Fire extinguisher | 0 | 0 | |

| Technical Documentation Package | CAD, Reports, Repo | Astro PDM, Github, Cloudflare | 0 | 0 |

| Precision Tools | Calipers, Micrometers, Gauges | 0 | 0 | |

| PIM Shooter 300A | Injection Molder | 0 | 0 | |

| Formech 450DT | Thermoformer | 0 | 0 |

2.3 Cost Breakdown by Category

| Category | Line Items | Subtotal ($) | Percentage (%) |

|---|---|---|---|

| Air Flow | 3 | 0.00 | 0.0 |

| Contingency & Misc | 2 | 26.00 | 4.5 |

| Control & Electrical | 3 | 50.00 | 8.6 |

| Instrument & Data | 5 | 69.00 | 11.9 |

| Materials & Structure | 9 | 434.27 | 75.0 |

3. CONFIGURATION B: ENHANCED BUDGET

3.1 Complete Bill of Materials

| Line | Part Number | Description | Notes | Qty | Unit Cost ($) | Total Cost ($) | Category |

|---|---|---|---|---|---|---|---|

| 1 | N/A | PETG Filament, 1.75 mm | 1 kg spool | 8 | 24 | 192 | Materials & Structure |

| 2 | N/A | Acrylic Sheet (2-pack) | 24″×36″ | 4 | 28 | 112 | Materials & Structure |

| 3 | N/A | MDF Board | 16″×20″ | 10 | 15 | 150 | Materials & Structure |

| 4 | N/A | Marine Plywood | 4′×8′ panel | 1 | 85 | 85 | Materials & Structure |

| 5 | N/A | Contraction/Diffuser | CNC machined | 1 | 120 | 120 | Materials & Structure |

| 6 | Fabricated | Polycarbonate Panels | UV-resistant | 4 | 35 | 140 | Materials & Structure |

| 7 | Fabricated | Silicone Gaskets | High-temp cut | 1 | 35 | 35 | Materials & Structure |

| 8 | N/A | Precision Fastener Kit | Traceable hardware | 1 | 62 | 62 | Materials & Structure |

| 9 | Unknown | Load Cell 0–5 kg (precision) | High accuracy | 3 | 12 | 36 | Instrument & Data |

| 10 | Fabricated | Precision Sting Mount | CNC/lathe | 1 | 45 | 45 | Instrument & Data |

| 11 | Unknown | 24-bit ADC | High-res converter | 2 | 8 | 16 | Instrument & Data |

| 12 | Unknown | Pitot-Static Probe | Lab-grade | 1 | 35 | 35 | Instrument & Data |

| 13 | Unknown | Digital Pressure Transducer | USB output | 2 | 25 | 50 | Instrument & Data |

| 14 | Unknown | USB Data Logger | For ADC | 1 | 18 | 18 | Instrument & Data |

| 15 | Unknown | Hot-wire Anemometer | 0.05–50 m/s | 1 | 55 | 55 | Instrument & Data |

| 16 | Unknown | Calibration Weight Set | 100 g–1 kg | 1 | 35 | 35 | Instrument & Data |

| 17 | Fabricated | Honeycomb Flow Straightener | Grid flow | 1 | 45 | 45 | Air Flow |

| 18 | Unknown | Turbulence Screens (40 mesh) | 4 units | 4 | 15 | 60 | Air Flow |

| 19 | Unknown | Centrifugal Blower | 120 V, 3000 RPM | 1 | 120 | 120 | Air Flow |

| 20 | Unknown | ESP32 Dev Board | Wi-Fi/BT | 1 | 55 | 55 | Control & Electrical |

| 21 | Unknown | Digital Servo 20 kg·cm | Metal gear | 2 | 25 | 50 | Control & Electrical |

| 22 | Unknown | Regulated 24 V Power Supply | 10 A, EMI filtered | 1 | 85 | 85 | Control & Electrical |

| 23 | Unknown | 7″ TFT Display | Touchscreen HDMI | 1 | 45 | 45 | Control & Electrical |

| 24 | Unknown | Professional Smoke Generator | 1000 W DMX | 1 | 65 | 65 | Contingency & Misc |

| 25 | Unknown | LED Light Bar | 5000 K dimmable | 1 | 30 | 30 | Contingency & Misc |

| 26 | Fabricated | Vibration Isolation Mounts | Rubber-steel | 1 | 40 | 40 | Contingency & Misc |

| 27 | Unknown | Project Contingency Reserve | 5% materials/shipping | 1 | 100 | 100 | Contingency & Misc |

Configuration B Total: $1,881.00

3.2 Equipment List

| Equipment | Description | Notes | Unit Cost ($) | Total Cost ($) |

|---|---|---|---|---|

| Bamboo H2D | 3D Printer | Used for fabricating PLA structural parts and small fixtures | 0 | 0 |

| EPILOG HELIX | Laser Cutter | Used for cutting acrylic panels and MDF sheets | 0 | 0 |

| Professional Smoke Generator | Airflow Visualization Device | 65 | 65 | |

| Safety | Eye Protection, Fire Extinguisher | 0 | 0 | |

| Technical Documentation Package | CAD, Reports, Repo | Astro PDM, Github, Cloudflare | 0 | 0 |

| Precision Tools | Calipers, Micrometers, Gauges | Astro PDM, Github, Cloudflare | 0 | 0 |

| PIM Shooter 300A | Injection Molder | 0 | 0 | |

| Formech 450DT | Thermoformer | 0 | 0 | |

| CNC Machine | Precision Machining | 0 | 0 |

3.3 Cost Breakdown by Category

| Category | Line Items | Subtotal ($) | Percentage (%) |

|---|---|---|---|

| Air Flow | 3 | 225 | 11.96 |

| Contingency & Misc | 4 | 235 | 12.49 |

| Control & Electrical | 4 | 235 | 12.49 |

| Instrument & Data | 8 | 290 | 15.42 |

| Materials & Structure | 8 | 896 | 47.63 |

4. HEAD-TO-HEAD COMPARISON

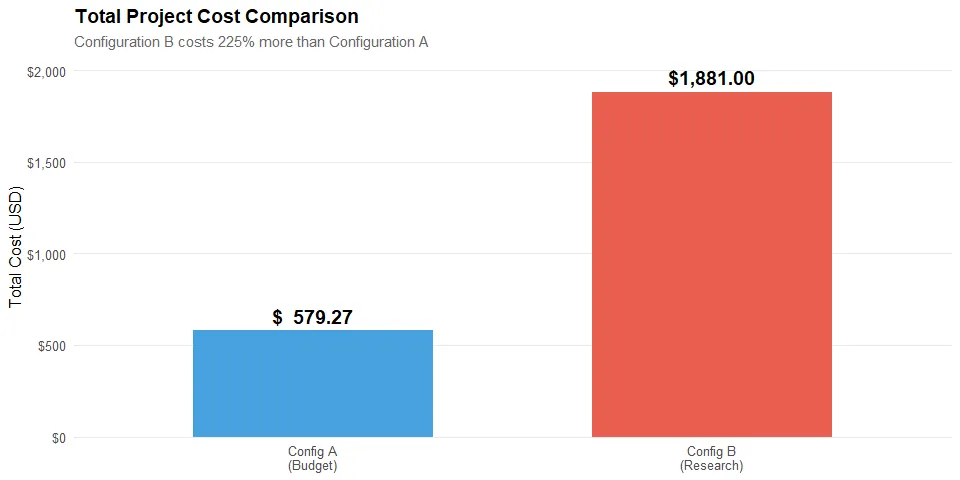

4.1 Cost Summary

| Metric | Configuration A | Configuration B | Delta (B - A) |

|---|---|---|---|

| Total Material Cost | $579.27 | $1,881 | + $1,301.73 |

| Number of Line Items | 22 | 27 | +5 |

| Average Cost per Item | $26.33045 | $69.66667 | + $43.33621 |

| Highest Single Item | PLA Filament, 1.75 mm $140 | PETG Filament, 1.75 mm $192 | + $52 |

| Salvaged Components | 7 items ($0) | 0 items | -7 items |

| Contingency Reserve | $20 | $100 | + $80 |

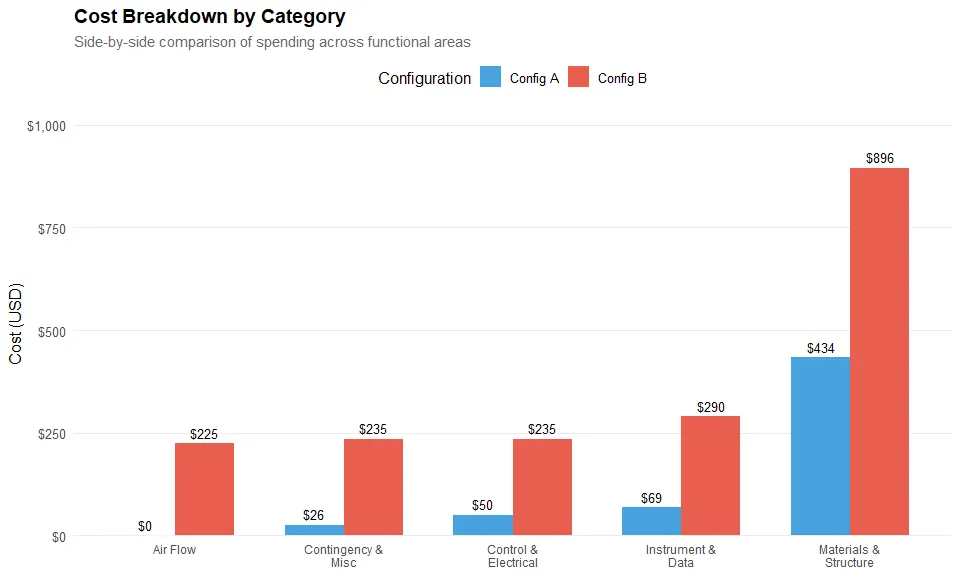

4.2 Category Spending Comparison

| Category | Config A ($) | Config B ($) | Delta ($) |

|---|---|---|---|

| Air Flow | 0.00 | 225 | 225.00 |

| Contingency & Misc | 26.00 | 235 | 209.00 |

| Control & Electrical | 50.00 | 235 | 185.00 |

| Instrument & Data | 69.00 | 290 | 221.00 |

| Materials & Structure | 434.27 | 896 | 461.73 |

4.3 Key Differences

Configuration A (Budget Build)

- Relies on salvaged components

- Manual data recording required

- Basic analog sensors

- Single-speed fan operation

- Simple Arduino Uno controller

- Propylene glycol fog for visualization

Configuration B

- All purchased components

- Automated data logging with USB interface

- Digital sensors with documented accuracy

- Variable speed blower with VFD capability

- Enhanced structural integrity with higher-durability materials

5. OUR TAKE

5.1 Reality Check

Config A is doable on a student budget due to our access to salvaged parts and free equipment. We estimate the cost to replicate for a third-party would be 200-300 dollars higher solely for materials.

Config B is more expensive but better suited for research. It would also allow for more long-term use of the Wind Tunnel.

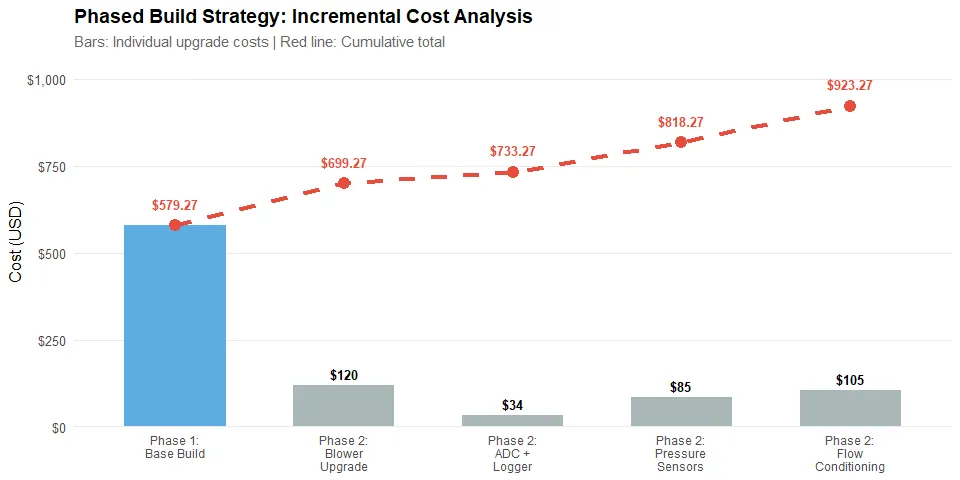

5.2 Plan

Phase 1 Priorities:

- Build the tunnel structure (Config A)

- Get basic flow visualization working

- Validate velocity measurement with pitot tube

Phase 2 Upgrades (if budget allows):

- Swap to centrifugal blower (+ $120) → better flow control

- Add 24-bit ADC + data logger (+ $34) → automated logging

- Upgrade pressure sensors (+ $85) → better accuracy

- Add flow conditioning (+ $105) → improved flow quality

6. APPENDICES

6.1 Abbreviations

- ADC = Analog-to-Digital Converter

- BOM = Bill of Materials

- CFD = Computational Fluid Dynamics

- CNC = Computer Numerical Control

- EMI = Electromagnetic Interference

- FS = Full Scale

- I2C = Inter-Integrated Circuit (serial protocol)

- MDF = Medium-Density Fiberboard

- NIST = National Institute of Standards and Technology

- PETG = Polyethylene Terephthalate Glycol

- PLA = Polylactic Acid (3D printer filament)

- PWM = Pulse Width Modulation

- TIR = Total Indicator Runout

- USB = Universal Serial Bus

- VFD = Variable Frequency Drive

6.2 Version History

| Version | Date | Author | Changes |

|---|---|---|---|

| 0.1 | 2025-9-26 | Jacob & Noah | Initial Setup of BOM |

| 0.2 | 2025-9-27 | Jacob & Noah | Budget A and Budget B |

| 0.3 | 2025-10-02 | Jacob Poore | Initial Price Sourcing |

| 0.4 | 2025-10-04 | Jacob Poore | Added visualization graphs |

| 1.0 | 2025-10-04 | Jacob Poore | First Release |

License:

| Component | License |

|---|---|

| Hardware & Software | MIT |

| BOM & Documentation | CC BY 4.0 |